Maker Drive is designed base on feedback from users, especially 1st time user.

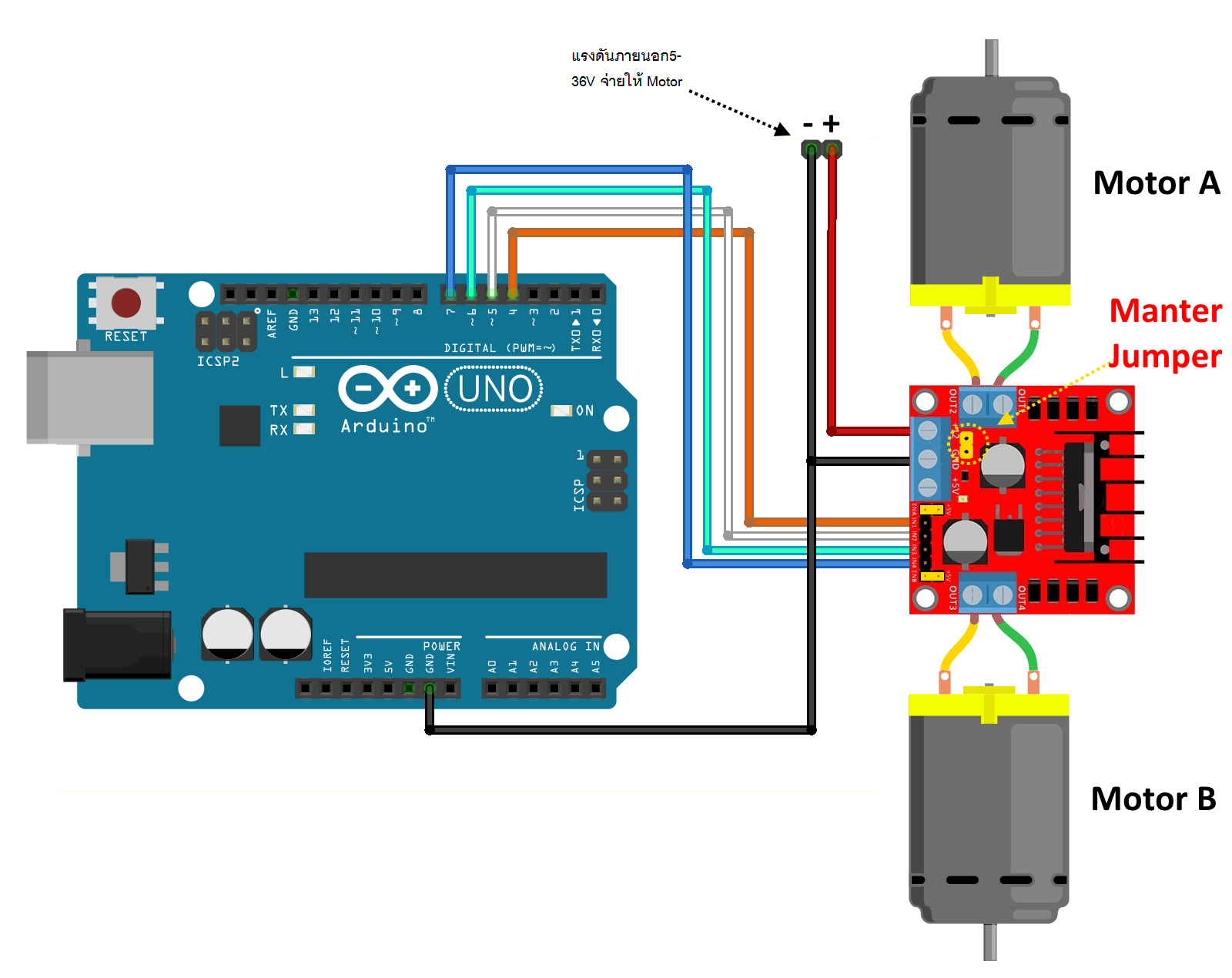

The Problem Faced by Beginners in Driving DC Brushed Motor But if you want an easy and beginner-friendly motor driver, you are on the right page! Maker Drive is designed for simplicity and with the beginner in mind! Just supply the two terminals with DC power, the motor will start rotating! If you want to control its speed and direction using a controller, usually you will use an L298N Motor Driver. Pot Magnets with Cylindrical Borehole Screw-onīrushed motor is the most widely used motor because it is easy to use.Adjustable Step Up / Step Down Power Supplies.12 V Step Up / Step Down Power Supplies.3.3 V Step Up / Step Down Power Supplies.See FAQ:Where can I find “specific part” for information about looking for existing part files, and information needed to create new parts. Either as is, or as a base for something else. I would not try to use that downloaded part with out some serious cleanup first. To figure out where things are supposed to be, and what should be connected together. To do this properly, a datasheet for the part is really needed. What I see does not have labels except on breadboard, and the part validation tool I use has many complaints. Jumper wires (or cable) would run from the board to a header on the pcb instead. Really, this board does not normally need a pcb view. Spacing and position of the pins on the pcb view also look off. I do not see any of that in the part definition though. Like multiple gnd, or +5V connecting to other +5. Wires are not connecting where they are dragged to except in breadboard view.įewer pins in schematic “CAN” be normal, in cases where multiple physical pins are connected together inside the part. My initial testing of a fresh download of that part says it is broken.

0 kommentar(er)

0 kommentar(er)